MAGNETIC PARTICLE TESTING

Magnetic particle testing is a procedure to detect cracks on or near the surface of ferromagnetic (magnetizable) materials. With the help of previously applied inspection fluids, cracks, pores or other anomalies become visible by magnetizing the workpiece in part or as a whole.

Procedure description:

A precleaning is executed mechanically or chemically. The component’s surface has to be free of cinder, rust, oil, fats and the like.

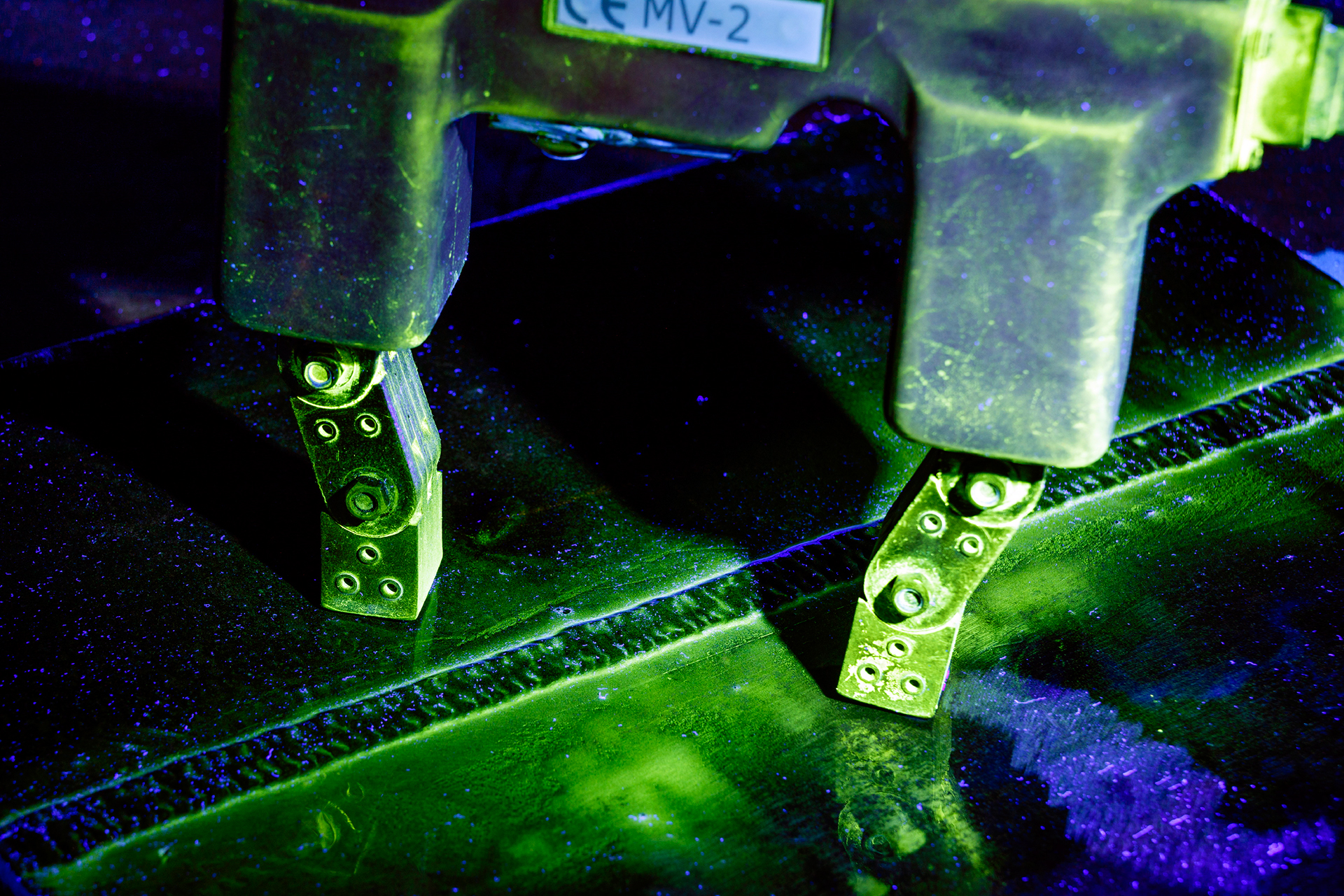

Firstly, when the black-and-white inspection is used to test the workpiece, a layer of white color is applied on the cleaned surface. A black magnetic powder spray is then added during the magnetization. In contrast, the fluorescent inspection requires a fluorescent black magnetic powder which is sprayed directly onto the workpiece during its magnetization. The magnetization itself is carried out with the help of manual yoke magnets, through portable or wheeled power generators or via magnetizing coils.

The black-and-white inspection can be executed by daylight, whereas the workpiece is examined under UV-A light when the fluorescent magnetic powder spray is employed

Downloads: